PCB Thermal Management Solution

As a solution to modern PCB thermal management issues, GSPK has created a, patent pending, novel Direct Thermal Exchange Technology.

PCBs are getting more powerful and as a result of denser packaging more complex thermal management challenges have to be addressed. There has never been a greater requirement to transfer heat away from components. Conduction via the circuit to a heatsink or cool plate is the usual way to do this.

The design and construction of the PCB and Thermal Conductivity of the materials used will affect how effectively these thermal problems are handled.

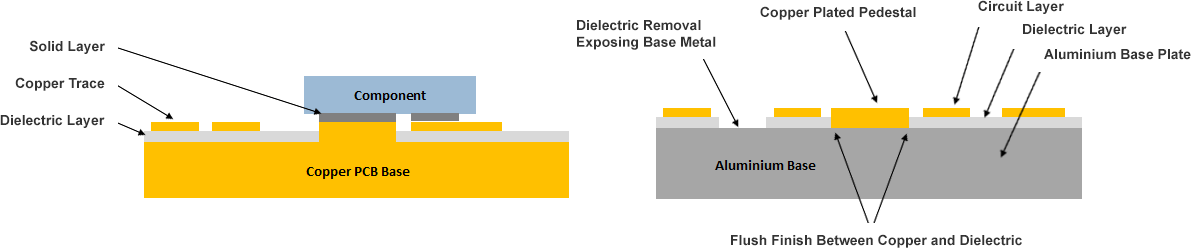

PCBs with ceramic substrates are becoming more popular as their thermal conductivity values are between 24 and 180 W/mK. This innovative technology is not appropriate for all applications due to production limitations including size and cost. Many people find that IMS (Insulated Metal Substrates) are a good solution. They were first developed to fight the growing junction temperatures of surface mount components on LEDs. They are composed of an aluminium/copper foundation and a thermally effective electrical isolating dielectric layer between the copper tracks and an aluminium/copper base. GSPK can offer multi-layer IMS boards. Thermal limits for aluminium IMS typically range from 8 to 10 W/mK.

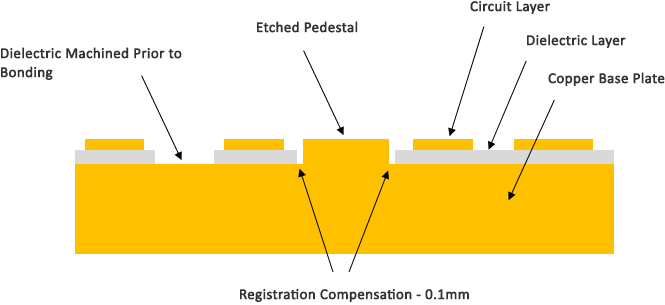

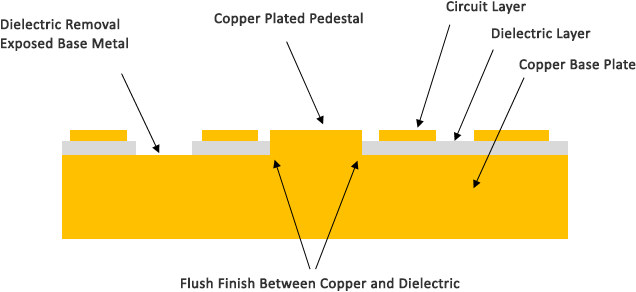

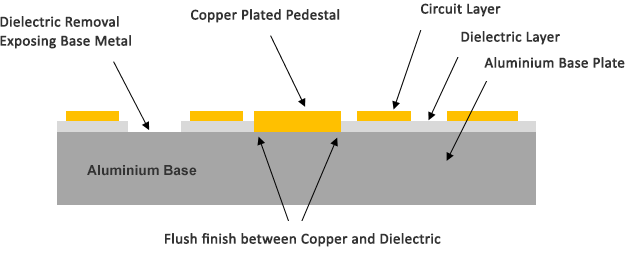

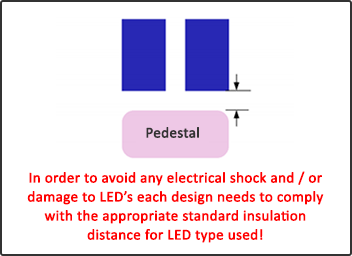

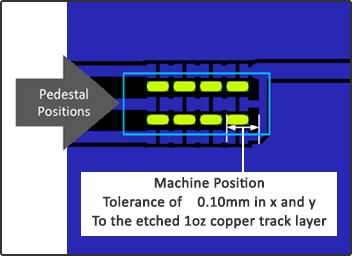

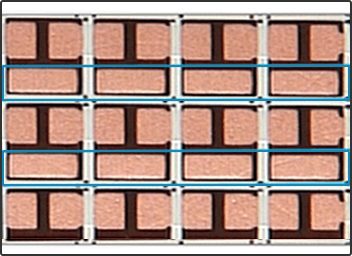

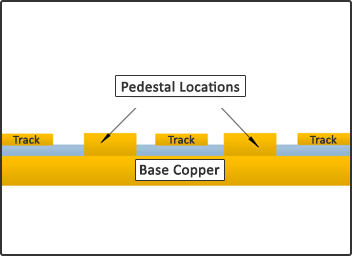

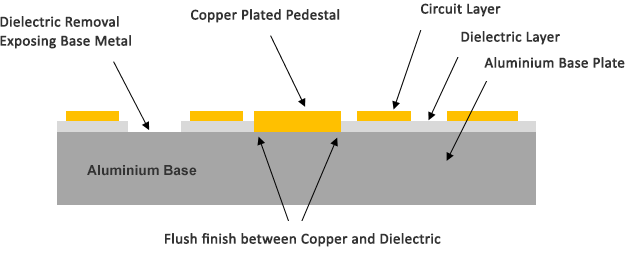

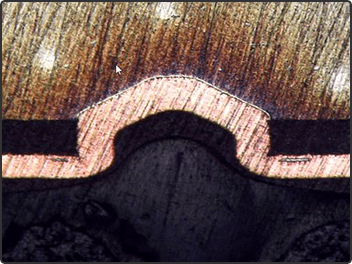

IMS boards' thermal efficiency is increased even more by DTE - Direct Thermal Exchange Technology. The dielectric layer is a metal core IMS's primary thermal bottleneck, however with DTE, the dielectric layer is avoided by a plated, direct connection to the base layer. These connections are also know as Pedestals. This bypass allows for the heat to be delivered with reduced thermal resistance, controlling component temperature, extending component lifetime, and improving operational performance. Building pedestals is more dependable than thermal vias because of their greater copper mass and efficiency, which ensures that the heat is distributed more evenly and is transferred to the heatsink more effectively.

Up until this point, copper, which is heavy and expensive, served as the DTE base layer. GSPK provides DTE using a copper base, but we just created a patent-pending method that enables the plated copper connection to attach to an aluminium base, offering the conventional heatsinking materials of copper to aluminium. Using our technology, we can guarantee that the DTE (pedestal) will not split from the aluminium base and has successfully endured 1,000 thermal shock cycles.

Compared to copper base DTE, aluminium base DTE offers the following four clear benefits:

| Base Copper Weight (Thickness) | Standard | Special | |

|---|---|---|---|

| Minimum Track Width | 0.5oz (18um) | 0.10 | <0.10 |

| 1oz (35um) | 0.10 | <0.10 | |

| 2oz (70um) | 0.20 | <0.20 | |

| 3oz (105um) | 0.25 | <0.25 | |

| Minimum Track Gap | 0.5oz (18um) | 0.10 | <0.10 |

| 1oz (35um) | 0.15 | <0.15 | |

| 2oz (70um) | 0.20 | <0.20 | |

| 3oz (105um) | 0.25 | <0.25 |

| Hole Data | Standard | Special |

|---|---|---|

| Minimum Hole Size | 0.5 | 0.2 |

| Hole Tolerance - Drilled | ±0.05 | ±0.03 |

| Hole Tolerance - Routed Holes | ±0.10 | +0 /-0.05 |

| Minimum Hole to Edge | 0.10 | <0.10 |

| Hole to Edge Tolerance | ±0.15 | ±0.10 |

| Minimum Radial Clearance Pad (Annulus) | 0.1 | 0.075 |

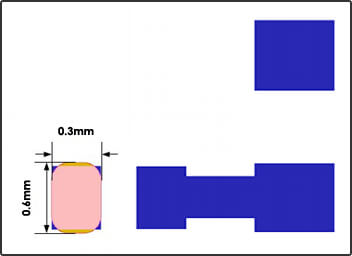

Min Pedestal Size

Min Pedestal Size Max Pedestal Size

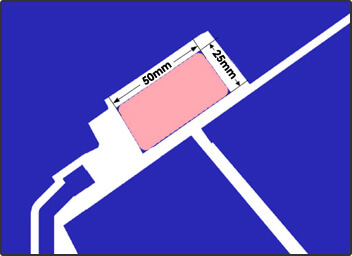

Max Pedestal Size Pedestal Gap

Pedestal GapCopper to Aluminium bond has passed the 1000 cycle test for thermal shock.

| Number of Test Cycle (NCYCLE) | 1000 |

| Minimum Chamber Temperature (Tmin) | -40°C |

| Maximum Chamber Temperature (Tmax) | +125°C |

| Transfer Time (t2) between Chambers | ≤10 S |

| Dwell Time (t) at low/high temp | 15 minutes |

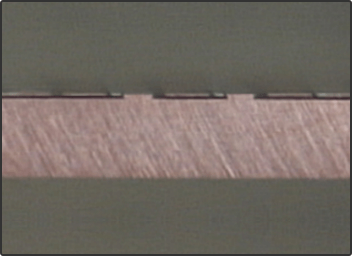

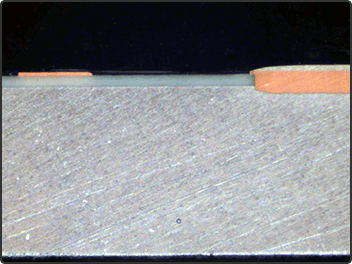

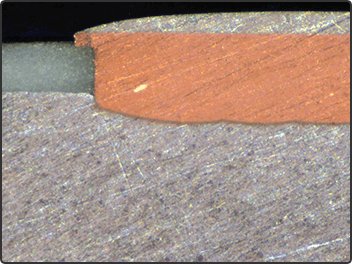

These pictures demonstrate GSPK's DTE technology, plating a copper pedestal through a dielectric to bond permanently to an aluminium base.

Can also be used as a microvia for current, connecting copper to aluminium so that the base layer can operate as a ground layer.

The microsection pictured here was created following a 1000 cycle test for thermal shock.